gerry

Reviewer

5/5

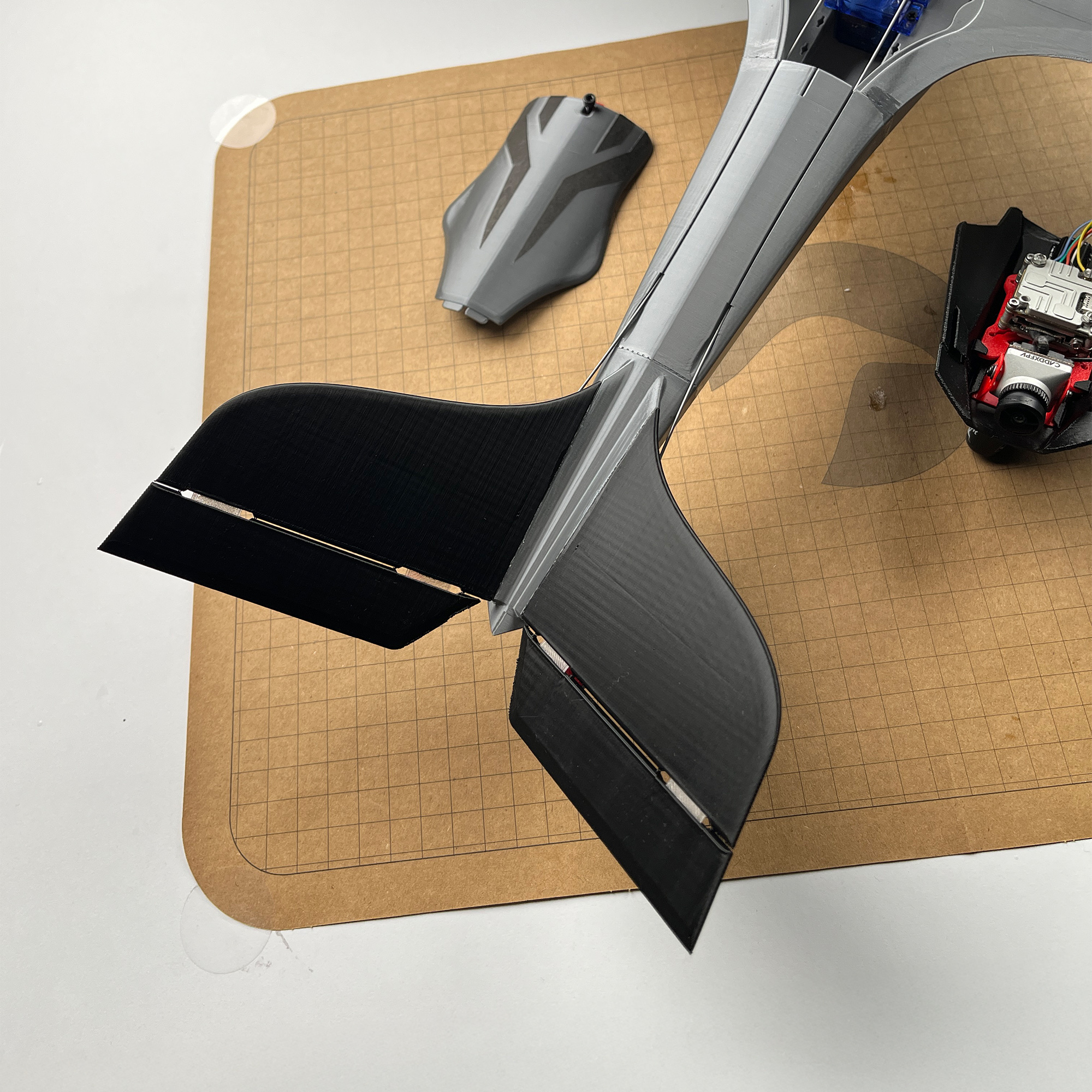

I downloaded the free fuselage files to test the product. Perfect print on my Creality HI. Even with standard PLA the weight is good.

2 weeks ago

SirSavio

5/5

This is a great model. All the construction is easy, the parts fits together smoothly. All the build was done em 1 hour, good!

1 month ago

aydn35hlm

Reviewer

4/5

Merhabalar uçağı direkt kit halinde satın aldım fakat arka sağ elevatör sol ile aynı geldi tekrardan STL olarak gönderme şansınız varmı

2 months ago

theodoresaxby

Reviewer

5/5

2 months ago

2emiruregen

Reviewer

5/5

bambulab yazıcım var aldıktan sonra gelen dosyaları bambu studioda açıp direk olarak hiçbir ayar değiştirmeden basabilecekmiyim?

3 months ago

hasanalpyildiz10

Reviewer

5/5

Merhabalar Öncelikle Bu kiti alacağım ve içinde anladığım kadar stl dosyaları mevcut değil onun için de ayrı olarak almam gerekecek değil mi ? ve bird...

Show More

Show More

e Bu projeyi yaptıktan sonra kontrol işlemi nasıl olacak ne üzerinden kontrol edeceğiz normal fiziki bir kumanda ile mi yani kite dahil mi yoksa telefon üzerinden falan mı kontrol edeceğiz ?

Show Less

Show Less

3 months ago

sahnyuk.s.s

5/5

I’m printing the model now, and it’s clear that a huge amount of work went into optimizing it. Even on my old printer, the parts come out perfectly.

...

Show More

Show More

Personally, I ran into an issue where some parts are too tall for my printer (my Z ~140 mm), but that’s just my own limitation — I’ll ask someone else to print those for me.

Once I finish this model, I’ll most likely buy the next one.

Thanks to the team for such high-quality work — I’m really satisfied!

Show Less

Show Less

4 months ago

Sawyer

Reviewer

5/5

5 months ago

theodoresaxby

Reviewer

5/5

5 months ago